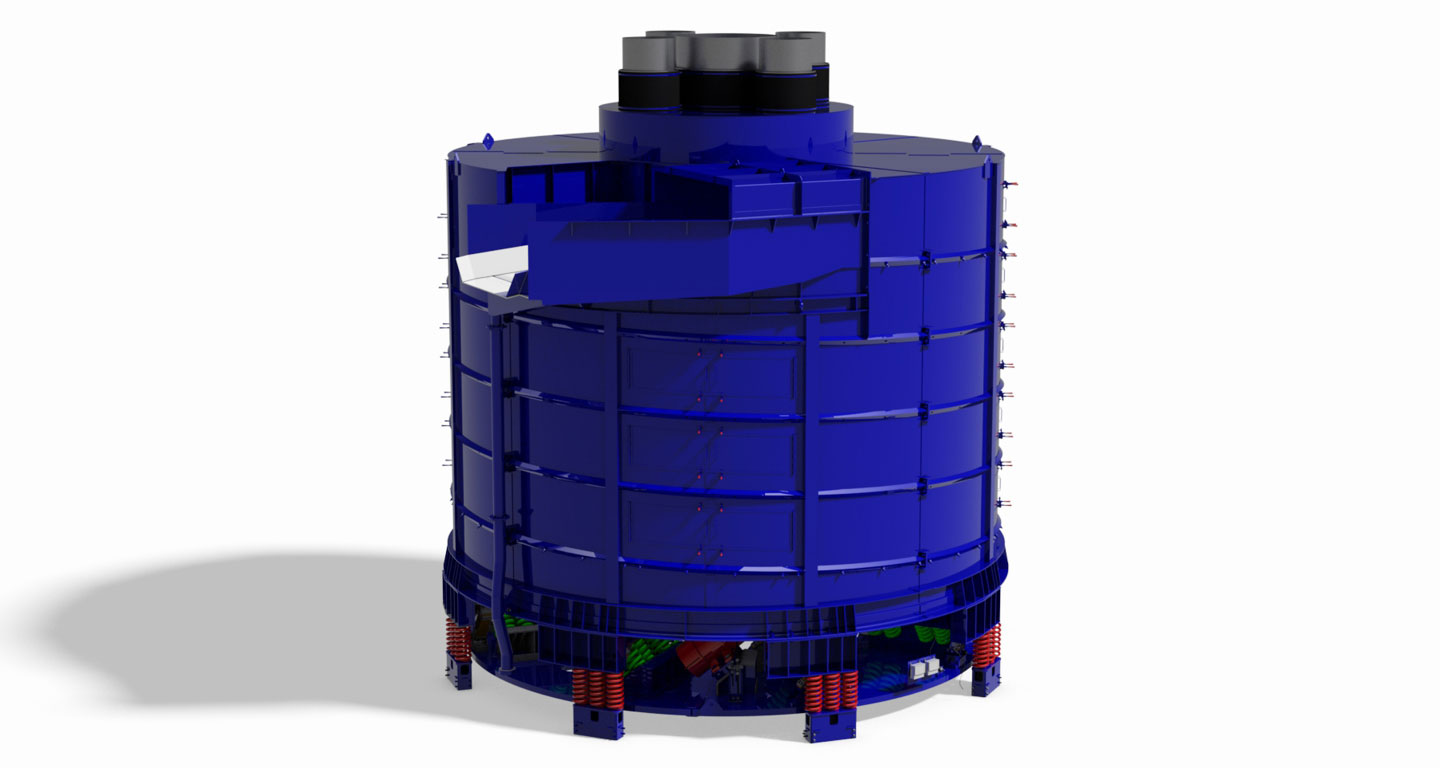

Vibrating spiral-cool towers are used to perform casting cooling in a minimum amount of space and significantly reduce floor-area. Designed to fit your processes, the spiral-cool tower can replace up to 400 feet of cooling conveyors, resulting in limited congestion floor areas. The design of the cold air chamber cools the casting pieces quietly and efficiently. The spiral design of the tower, combined with the vibratory motion, adequately places the parts to cool and avoids damage. A sand collection system may also be integrated in order to remove the sand, which can detach castings.

The spiral-cool towers are equipped with counterweight motors, which significantly reduce downtime and maintenance. Different configurations (dimensions, loading modes, unloading, etc.) are available to perfectly fit your needs.

Our spiral-cool towers meet CNESST security standards.

Contact Vibrotech for more information on our castings cooling solutions.