Customized heavy-duty and high-performance trommel screens.

Our trommel screens are known for being heavy duty and requiring minimal maintenance. Originally designed for harsh operations in plant handling construction, renovation and demolition recycling (CRD materials), their design ensures longer life.

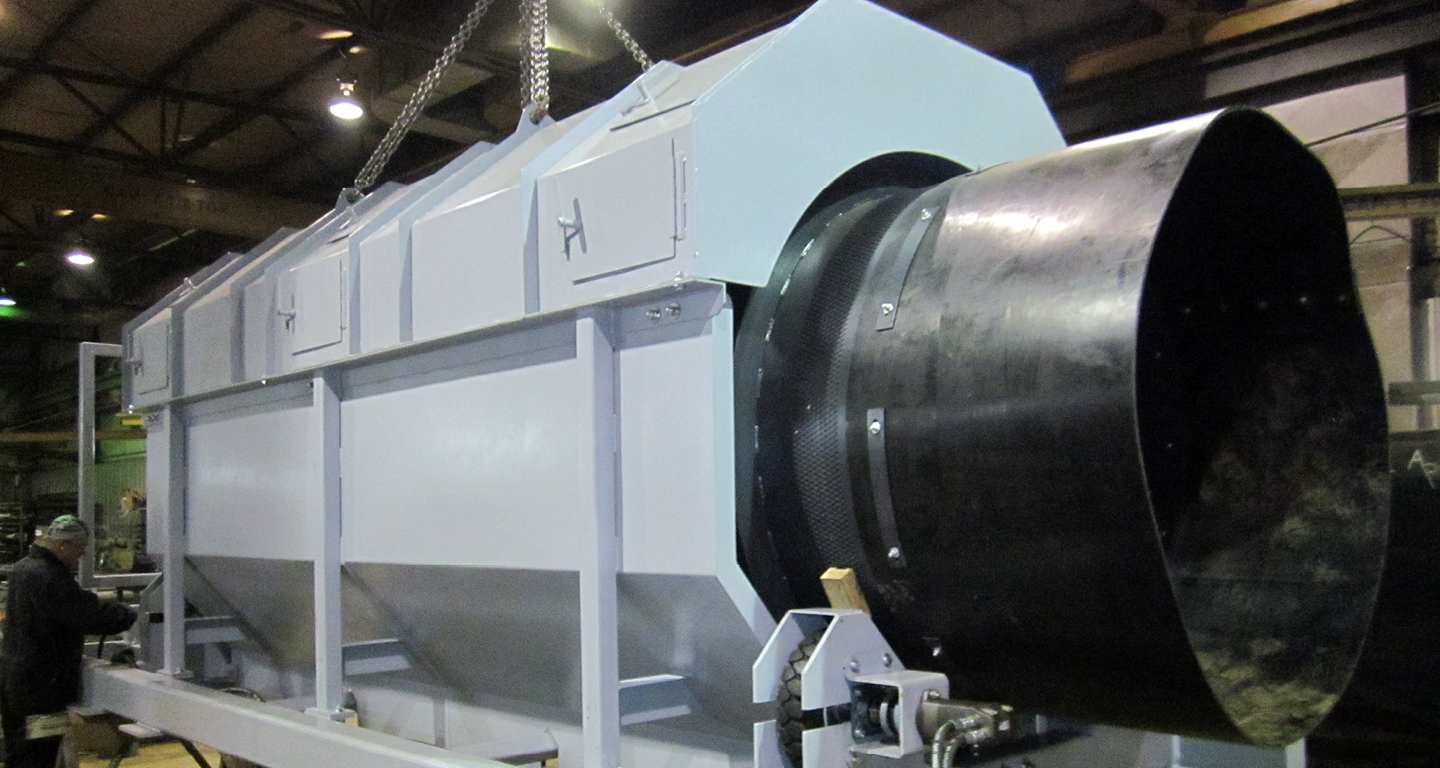

Our trommel screens are comprised of two important sections: the rotating drum and sub-structure/traction system.

The rotary trommel has a heavy-duty frame that makes up the structure of the drum. Diameters normally range from 4' to12'; the final size is selected based on your type of application. The screening length varies from 12' to 45', based on the application. Knowing how the rotating screen will be used is vital to choosing the critical parameters, such as the diameter (capacity), length and angle of inclination (retention time), size of screening needed (based on the desired product), and the rotation speed (optimizing the screening surface).

As for the general design, our concept facilitates maintenance. In fact, the drum sits on drive wheels mounted on axles, such as for trucks, to facilitate access when maintaining pars. The sections of the rotating screens are interchangeable plates cut from superior hardened steel to minimize wear. Should the size of the screen need to be changed, simply change the screens that fit into the frame of the drum.

Our trommel screens are equipped with safety guards for moving parts and meet CNESST security standards.