Vibratory reconditioners for sand have been proven in many foundry applications to restore the sand used for casting its initial properties. By its simplicity and low cost of operation, it often eliminates the need to use a larger and more expensive system—all while significantly improving sand recovery. Indeed, the effectiveness of Vibra-Mill reconditioners significantly reduces the purchase of new sand.

The processing capacity of up to 20 TPH can be maintained by reducing the mixture of sand agglomeration (sand casting) and an original sand size can be used.

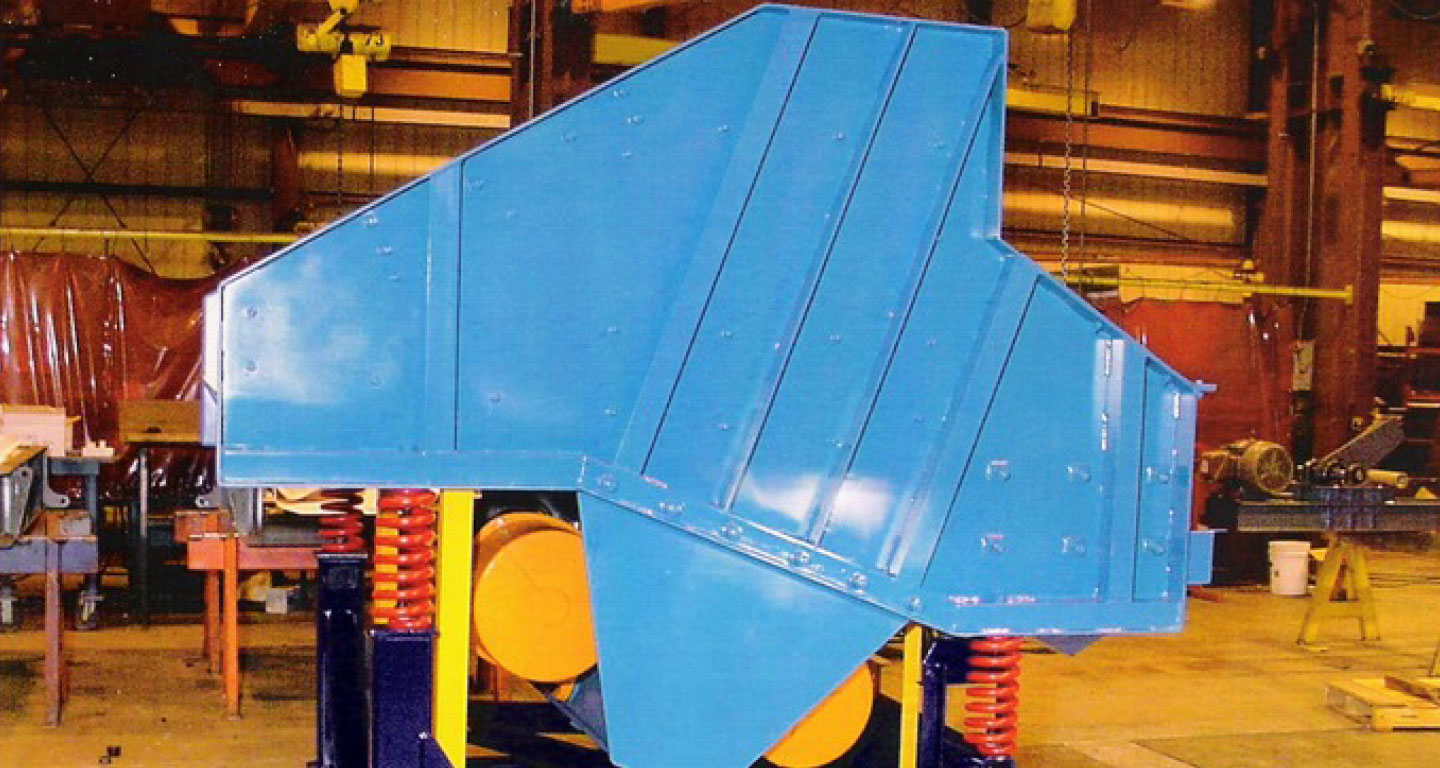

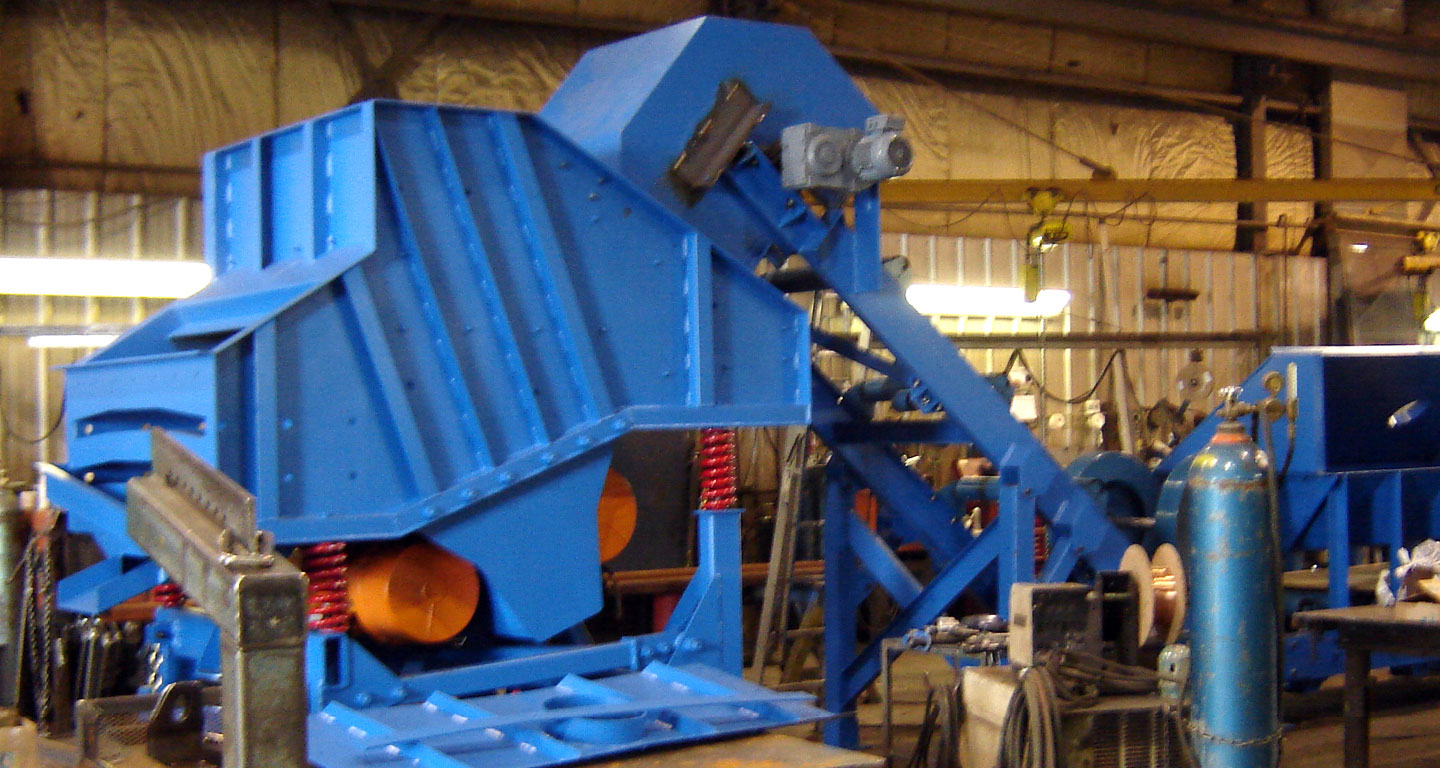

Vibra-Mill reconditioners are equipped with counterweight motors that significantly reduce downtimes and maintenance. Different configurations (dimensions, loading modes, unloading modes, etc.) are available to perfectly suit your needs

Vibra-Mill reconditioners are equipped with protective guards for moving parts and meet CNESST security standards.

Contact Vibrotech for more information concerning our sand reconditioners.